Joining Methods

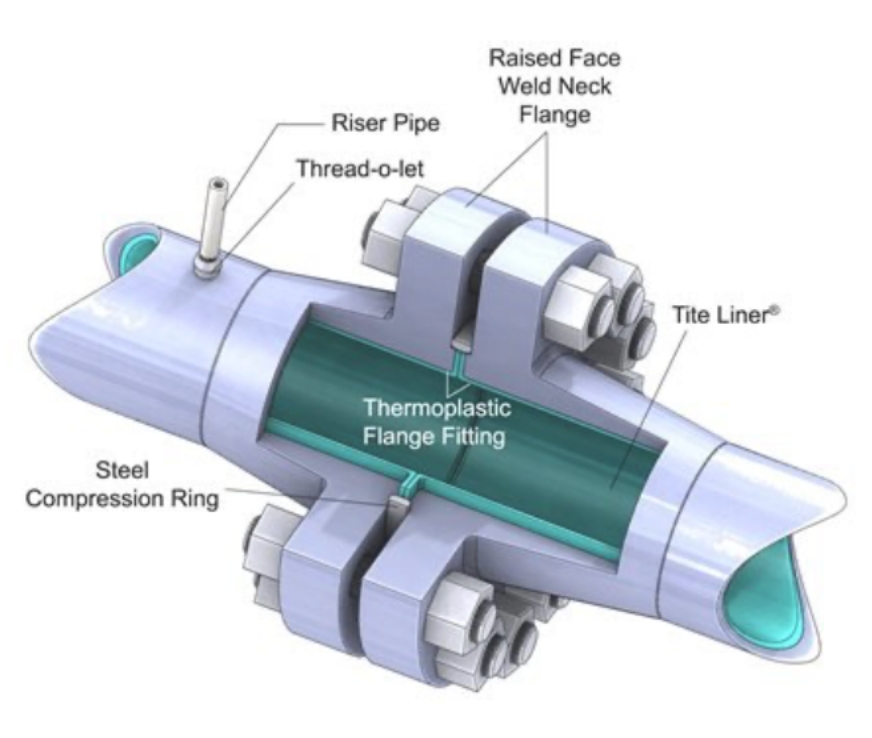

Tite Liner® system flange fittings provide a tight seal and restrained joint in extreme environments and under high pressure.

United Pipeline manufactures our fittings to exact dimensions to ensure superior performance of the completed flange connection.

Durable & Reliable Connections

Tite Liner® system flange Connection

Each raised-face steel flange is machined to match the inside diameter of the steel pipe and inspected to verify that the raised face dimension is correct. Each polyethylene flange-fitting is butt-fused to the end of the liner section and allowed to retract to fit tightly against the raised face of the steel flange. As two steel flanges are joined together, the polyethylene flange-fitting is compressed, creating a seal in the pipe system.

A spacer ring is placed between the steel flanges to provide the correct amount of compression of the liner flange. This compression creates the seal and the spacer ring adds long-term stability to the connection.

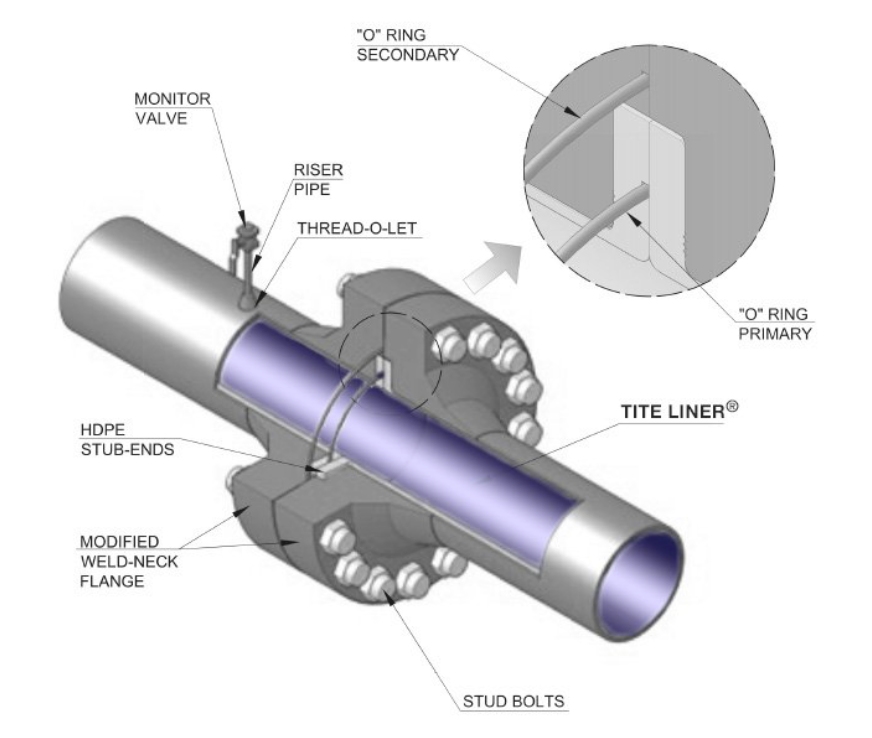

Posi-Seal Flange Connection

United developed the Posi-Seal Connection for these more demanding joining methods:

- High Pressure

- High Temperature

- Abrasive Flow Wear

- Dual Containment Seal

Posi-Seal flange connections utilize multiple self-energized seals and are designed to ASME B16.5 up to Class 2500 rating. United can provide the Posi-Seal Connection components along with the Tite Liner System.

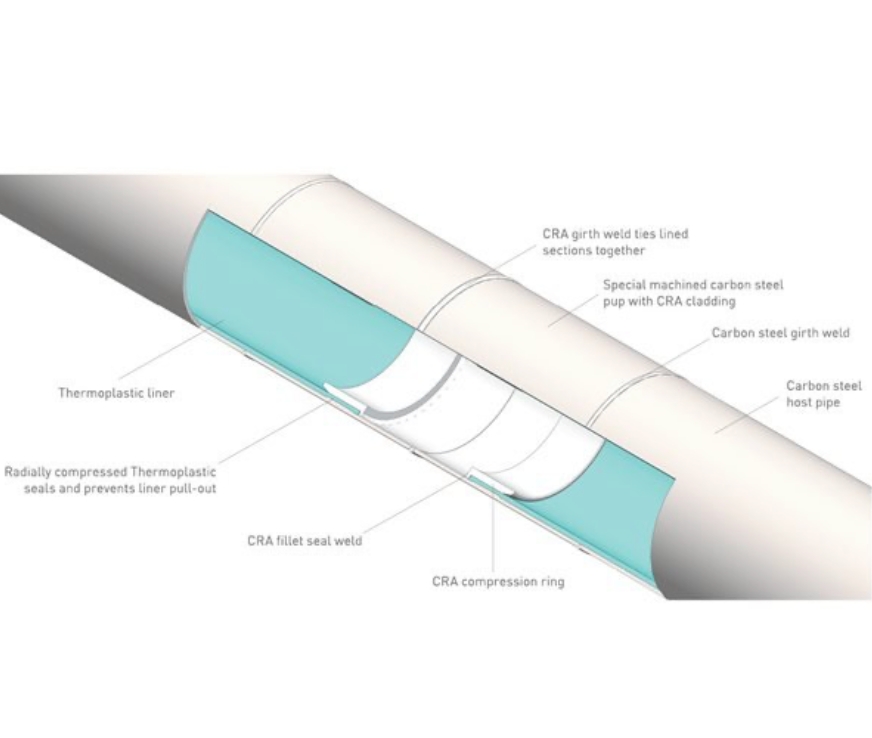

WeldTite® welded connection

The United Pipeline patented welded connection allows for the connection of two thermoplastic lined sections of steel pipe without the use of flanges. The connection creates an end seal on the thermoplastic liner which is tested to over 9,000 psi and materials are either thermoplastic or corrosion resistant alloy.

Other features include:

- U.S. and international patents

- Installation and operation complies with pipeline codes: ASME B31.3, ASME B31.4 and ASME B31.8

- United Pipeline Systems has installed more than 200 of these connectors to date

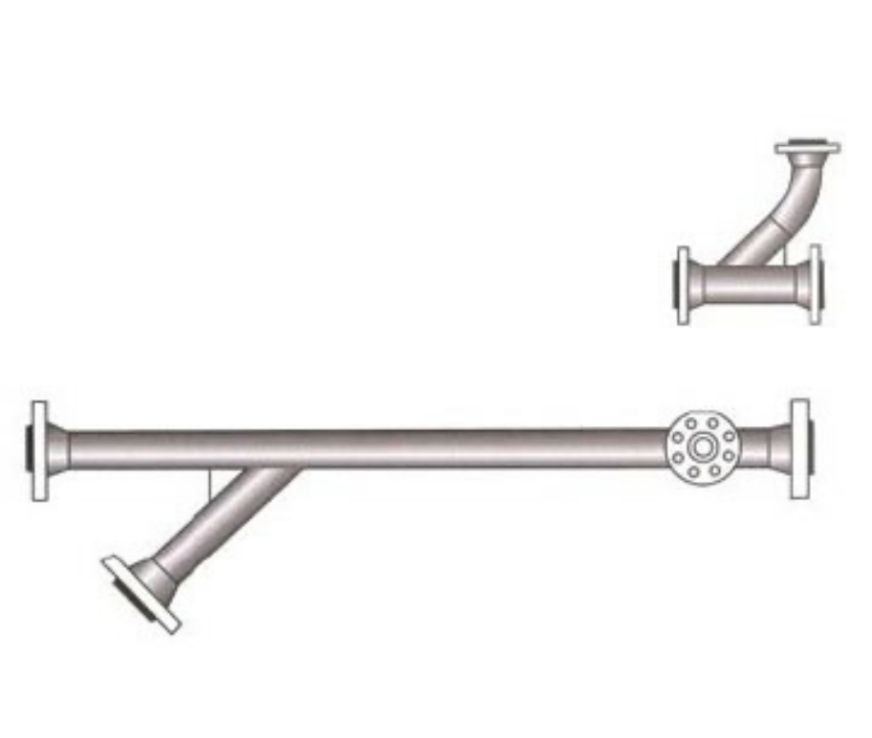

Spools and Fittings

The Tite Liner system offers complete protection for steel fittings used in abrasive and corrosive service for a complete polyethylene pipe lining solution. The thick thermoplastic pipe lining is factory applied and bonded to the inner wall of elbows, tees and other fittings.

These thermoplastic lined fittings are made exclusively to United Pipeline System’s specifications, ensuring a proper fit and a seal at all connections.