Protecting steel pipelines from corrosion and chemical wear is critical for long-term asset performance. High-density polyethylene (HDPE) liners have become a trusted solution, creating a durable barrier between the pipe wall and its contents. But for operators, one common question persists: how can lined pipelines be reliably inspected without disrupting operations?

Conventional inspection tools like Smart PIGs often face challenges in HDPE-lined pipelines, leading to the misconception that liners hinder inspection capabilities and limit long-term pipeline integrity monitoring. In reality, modern inspection technologies make it possible to monitor lined pipelines with precision, and Remote Field Testing (RFT) stands out as a proven, reliable method.

Inspection Challenges with Lined Pipelines

Thermoplastic liners provide critical protection for steel pipelines, but they can complicate inspection and maintenance strategies. Traditional inline inspection tools, commonly known as Smart PIGs, are designed to detect internal defects by traveling through the pipeline and collecting data. The most widely used method, Magnetic Flux Leakage (MFL), relies on direct magnetic interaction with the pipe wall to detect areas of wall loss or corrosion. However, MFL requires a strong, uninterrupted magnetic circuit, which is only possible when the sensors are in direct contact with bare steel.

In HDPE-lined pipelines, that contact is blocked. HDPE liners are non-magnetic, non-metallic, and acoustically dissimilar to steel, which disrupts the signal required for both MFL and Ultrasonic Testing (UT). These tools cannot penetrate the liner to assess the condition of the host pipe. As a result, some operators may believe they should avoid liners altogether, assuming they’ll lose the ability to monitor pipeline status. And since removing the liner for inspection is not practical, this hesitation can lead to missed opportunities for corrosion protection and pipeline rehabilitation.

These limitations are real, but so are the solutions. Modern inspection technologies now make it possible to inspect lined pipelines accurately without removing the liner or compromising the integrity of the system.

How RFT Enables Inspection Through Liners

One effective method for ensuring the long-term health and reliability of infrastructure systems is the use of Remote Field Testing (RFT). RFT is a non-destructive testing technique used to assess the pipes’ condition, requiring minimal system disruption. The pipeline inspection process begins with pipeline preparation, ensuring that the pipeline is clean and ready for inspection. Next, a gauge tool is launched into the pipeline to make sure there are not significant ID restrictions that would impede the RFT inspection tool from a successful deployment. Then the appropriate RFT probe is chosen based on the pipeline’s material, size, and any use of internal liners. During inspection, the RFT tool is launched into the pipeline. The probe moves through the pipeline at a steady pace while the data acquisition system captures signals for analysis. Once the data is captured, it is thoroughly analyzed to identify any anomalies that may indicate defects in the pipe wall. The location, length, and depth of these defects are determined by comparing the recorded signals with reference signals. Finally, the results are reported and documented according to applicable standards, including the type, location, and severity of any detected defects, ensuring comprehensive and accurate reporting of the inspection findings.

RFT tools contain an internal exciter coil that generates a low-frequency alternating current. This electromagnetic field passes through the pipe wall and induces eddy currents in the steel. These currents travel along the pipe and are detected by a series of receiver coils placed further down the tool. Because RFT’s sensing occurs at a distance, referred to as lift-off, it remains accurate even with thick liners or internal coatings. Tools can function with over 25mm of separation between the sensors and the steel surface.

The method has been in commercial use since the 1980s and is validated by organizations including the EPA, EPRI, and AWWARF. Companies like PICA lead the field in RFT application, making it a trusted, proven solution for inspecting lined steel pipelines without compromising protection or performance.

Figure 1 PICA’s Mid-Size RFT Tool: 36” Chimera

PICA Corp offers an array of Remote Field Eddy Current Testing (RFT) tools as part of its Advanced NDT Service Solutions, enabling the inspection of metallic pipelines for corrosion through internal liners and scale. This method is ideally suited for evaluating pipes with internal liners like cement mortar, HDPE, coal tar epoxy, and other protective coatings. A properly implemented RFT system deploys numerous detectors around the pipeline to generate high-resolution corrosion maps of the metallic cylinder. This methodology has demonstrated efficacy in evaluating cast iron, ductile iron, steel, bar-wrapped concrete cylinder, reinforced concrete cylinder, and prestressed concrete cylinder pipes (PCCP). PICA’s existing RFT tools include: SeeSnake, HydraSnake, Chimera, EMIT, and RAFT, each designed for specialized applications.

Figure 2.

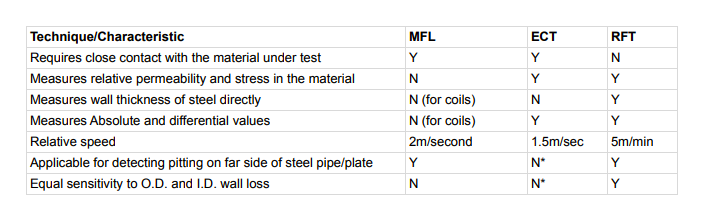

As shown in Figure 2, compared to Magnetic Flux Leakage Testing (MFL), RFT provides distinct advantages when inspecting pipelines with internal liners. MFL relies on a direct magnetic interaction with the pipe wall, which can be significantly hindered by non-metallic coatings and liners, thereby limiting its effectiveness in such applications. RFT utilizes an alternating electromagnetic field that can penetrate these barriers without interference, making it a more suitable method for lined pipelines. While MFL is highly effective in detecting localized defects in bare metal pipelines, RFT offers superior performance in assessing wall thickness variations and corrosion mapping in pipelines where direct contact with the metal surface is not feasible.

Why RFT is the Right Inspection Solution for Lined Pipelines

For operators working with HDPE-lined pipelines, having visibility into the pipeline’s structural integrity is essential. RFT offers a practical, proven method to detect critical issues by combining precision and versatility in a way few other inspection tools can.

Key advantages of RFT include:

- Liner-Compatible Accuracy – Inspects through HDPE and other non-metallic liners without signal distortion or loss of sensitivity.

- Dual-Side Wall Loss Detection – Measures both internal and external corrosion with equal reliability.

- Minimal Downtime or Liner Removal – Eliminates the need to cut or extract liners for inspection, reducing labor and operational delays.

- Structural and Performance Insights – Detects pitting, stress points, material thinning, and structural weaknesses.

- Rugged, Sensor-Protected Design – All sensors are enclosed within housings, making RFT tools mechanically reliable even in challenging environments.

With RFT, operators gain the ability to monitor pipeline integrity without sacrificing the protection a liner provides, making it the most practical choice for maintaining lined steel pipelines.

Pipeline Integrity Without Compromise

Thanks to technologies like RFT and experts like PICA Corp, maintaining lined pipelines is no longer a tradeoff between protection and inspection. Operators can now preserve steel assets against corrosion while still gathering the detailed data necessary for proactive maintenance and regulatory compliance.

United Pipeline Systems delivers industry-leading HDPE lining solutions that extend the life of critical infrastructure, and we work hand-in-hand with trusted inspection partners to ensure long-term performance. Whether you’re planning a new installation or maintaining existing assets, United’s team is here to help you protect your pipeline investment from day one.

Ready to move forward with confidence?

Contact United Pipeline Systems to learn how our Tite Liner® system and inspection-compatible solutions can support your next project, or reach out to PICA Corp to schedule an RFT inspection tailored to your needs.