Success Stories

Whether protecting new pipelines from corrosion and abrasion or rehabilitating existing pipelines, we combine high-quality, innovative solutions with unparalleled expertise, service and safety. Learn more about how United brings operational longevity to complex infrastructure.

Extending the Life of Mining Pipelines Under Abrasive Conditions

Mining operators around the world are facing renewed pressure on their pipeline infrastructure. Rising metal prices for copper, silver, and gold are driving increased production, particularly across the Southwest United States in Arizona and New Mexico. As output...

Expanding Critical Pipeline Infrastructure Beneath the Port of Long Beach

Background As one of the busiest ports in the United States, the Port of Long Beach serves as a major gateway for trans-Pacific trade and logistics. Beneath this vital maritime hub runs a complex network of critical utilities including fuel, water, and communications...

Trenchless Rehabilitation of Large Diameter Pipeline Infrastructure

Background - Norco Storm Water Inlet Basin A key infrastructure owner in the southeastern United States needed to rehabilitate three 48-inch steel pipelines running from a containment pond, under a concrete dam, and directly beneath a building constructed on top of...

Trenchless Dam Rehabilitation: How Municipalities Can Restore Outlets Without Draining Lakes

Across the United States, aging dams and reservoirs are presenting water managers and municipal agencies with a mounting challenge. Many of these structures were built decades ago and are now reaching or exceeding their intended design life. Beneath the surface,...

Underground Pipeline Reinforcement Via Horizontal Directional Drilling Below Colorado Highway

Background A raw water project along Colorado’s Highway 550 required durable underground pipeline crossings at two key locations. The 16-inch steel pipelines, buried beneath the roadway, would face risk of corrosion. Ensuring the long-term performance of these lines...

How HDD and Road Bores Keep Critical Projects Moving

Traditional pipeline installation often comes with trade-offs: road closures, lengthy permitting delays, and significant disruptions to surrounding communities. Trenchless construction methods offer a different approach by allowing crews to install underground...

How Salt Caverns Support Safe, Large-Scale Hydrocarbon Storage

Salt caverns play a critical role in energy infrastructure, but despite the term "brine caverns" sometimes being used, the storage itself happens in the salt formations, not in the brine. These underground systems are designed to store large volumes of hydrocarbons...

No Compromise Pipeline Integrity: HDPE Liner Installation & Remote Field Testing Explained

Protecting steel pipelines from corrosion and chemical wear is critical for long-term asset performance. High-density polyethylene (HDPE) liners have become a trusted solution, creating a durable barrier between the pipe wall and its contents. But for operators, one...

Rehab Of Failing Water Main In Historic Boston Common Park

Background Boston Water and Sewer Commission (BWSC) faced a failing pressurized water main along Beacon St., located underneath the historic Boston Common Park. The failing water main was located in a busy utility corridor with old growth trees directly above. To...

Upper Beaver Brook Dam Rehabilitation

Background The outlet pipe for the Upper Beaver Brook Dam just west of Denver, CO had reached a critical state of failure, posing a significant threat to the dam's functionality and the surrounding ecosystem. Replacing the pipe through traditional methods would have...

Underground Pipeline Reinforcement Via Horizontal Directional Drilling Below Colorado Highway

Background A raw water project along Colorado’s Highway 550 required durable underground pipeline crossings at two key locations. The 16-inch steel pipelines, buried beneath the roadway, would face risk of corrosion. Ensuring the long-term performance of these lines...

Proven Success: CO2 Production Pipelines Paving the Way for Reliable Transport in CCUS

Background Over 25 years ago, the operator of the McElmo Dome, a 203,000-acre natural carbon (CO2) source field located in southwestern Colorado, faced significant challenges with corrosion in their carbon steel gathering pipelines. CO2, particularly wet CO2, is...

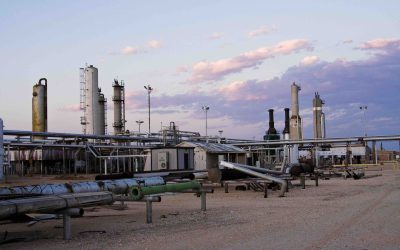

Internal Corrosion Control of Steel Pipelines Addressed at Underground Hydrocarbon Storage Facility in Mexico

November 2017 Underground salt dome storage facilities provide a safe and efficient means of storing hydrocarbons. The corrosion and abrasion issues related to handling brine, however, create integrity challenges that impact operational reliability and cost. A recent...

United Completes Longest Ever Tite Liner® Installation

Pipeline rehabilitation specialists, United Special Technical Services (USTS), a joint venture between United Pipeline Systems and STS, recently completed the longest-ever continuous compression fit Liner insertion project in its history. The project, undertaken using...

Extending the Life of Mining Pipelines Under Abrasive Conditions

Mining operators around the world are facing renewed pressure on their pipeline infrastructure. Rising metal prices for copper, silver, and gold are driving increased production, particularly across the Southwest United States in Arizona and New Mexico. As output...

Magnetite Iron Ore Mine Chooses the Tite Liner® System to Protect 270km Concentrate and Raw Water Pipelines in Western Australia

In 2022-2023, United Pipeline Systems installed the Tite Liner System in two 26” x 135 km pipelines for a client in Western Australia. One pipeline transports magnetite ore concentrate from the mine to the coast, while the other returns recycled water from the coast...

Underground Mine Selects United Pipeline Systems’ PreFit™ Solution for Production Line in Tunnel

Some pipeline applications require a small installation footprint. Instead of the typical field liner installation where a crew installs Tite Liner® on-site, PreFit™ pipe is lined offsite. The lined pipe is delivered by truck, ready for installation with...

Trenchless Rehabilitation of Large Diameter Pipeline Infrastructure

Background - Norco Storm Water Inlet Basin A key infrastructure owner in the southeastern United States needed to rehabilitate three 48-inch steel pipelines running from a containment pond, under a concrete dam, and directly beneath a building constructed on top of...

Trenchless Dam Rehabilitation: How Municipalities Can Restore Outlets Without Draining Lakes

Across the United States, aging dams and reservoirs are presenting water managers and municipal agencies with a mounting challenge. Many of these structures were built decades ago and are now reaching or exceeding their intended design life. Beneath the surface,...

Underground Pipeline Reinforcement Via Horizontal Directional Drilling Below Colorado Highway

Background A raw water project along Colorado’s Highway 550 required durable underground pipeline crossings at two key locations. The 16-inch steel pipelines, buried beneath the roadway, would face risk of corrosion. Ensuring the long-term performance of these lines...

How HDD and Road Bores Keep Critical Projects Moving

Traditional pipeline installation often comes with trade-offs: road closures, lengthy permitting delays, and significant disruptions to surrounding communities. Trenchless construction methods offer a different approach by allowing crews to install underground...

How Salt Caverns Support Safe, Large-Scale Hydrocarbon Storage

Salt caverns play a critical role in energy infrastructure, but despite the term "brine caverns" sometimes being used, the storage itself happens in the salt formations, not in the brine. These underground systems are designed to store large volumes of hydrocarbons...

No Compromise Pipeline Integrity: HDPE Liner Installation & Remote Field Testing Explained

Protecting steel pipelines from corrosion and chemical wear is critical for long-term asset performance. High-density polyethylene (HDPE) liners have become a trusted solution, creating a durable barrier between the pipe wall and its contents. But for operators, one...

Rehab Of Failing Water Main In Historic Boston Common Park

Background Boston Water and Sewer Commission (BWSC) faced a failing pressurized water main along Beacon St., located underneath the historic Boston Common Park. The failing water main was located in a busy utility corridor with old growth trees directly above. To...

Upper Beaver Brook Dam Rehabilitation

Background The outlet pipe for the Upper Beaver Brook Dam just west of Denver, CO had reached a critical state of failure, posing a significant threat to the dam's functionality and the surrounding ecosystem. Replacing the pipe through traditional methods would have...

Compressed Fit Liner Restores Weber Basin Water Transmission Line

Background In East Layton, Utah, the Weber Basin water transmission line faced a critical challenge with its aging infrastructure. The concrete pipeline, operating under pressures of up to 100 psi, was leaking at multiple joints. These leaks threatened the efficiency...

Tite Liner® Valley Forge Emergency Repair Project

When a force main suffered a major failure in Valley Forge National Park in Pennsylvania, Tredyffrin Township pledged to immediately repair or replace the pipeline. Assessment of the 18,000 ft. force main, a pre-stressed concrete cylinder pipe (PCCP) built in the...

Expanding Critical Pipeline Infrastructure Beneath the Port of Long Beach

Background As one of the busiest ports in the United States, the Port of Long Beach serves as a major gateway for trans-Pacific trade and logistics. Beneath this vital maritime hub runs a complex network of critical utilities including fuel, water, and communications...

Underground Pipeline Reinforcement Via Horizontal Directional Drilling Below Colorado Highway

Background A raw water project along Colorado’s Highway 550 required durable underground pipeline crossings at two key locations. The 16-inch steel pipelines, buried beneath the roadway, would face risk of corrosion. Ensuring the long-term performance of these lines...

Preserving Pipeline Integrity in the Permian Basin

Background The Permian Basin is one of the most prolific oil and gas producing regions in the world, with extensive infrastructure required to transport produced water, a byproduct of hydrocarbon extraction. Produced water is highly corrosive, containing a mix...

Proven Success: CO2 Production Pipelines Paving the Way for Reliable Transport in CCUS

Background Over 25 years ago, the operator of the McElmo Dome, a 203,000-acre natural carbon (CO2) source field located in southwestern Colorado, faced significant challenges with corrosion in their carbon steel gathering pipelines. CO2, particularly wet CO2, is...

Internal Corrosion Control of Steel Pipelines Addressed at Underground Hydrocarbon Storage Facility in Mexico

November 2017 Underground salt dome storage facilities provide a safe and efficient means of storing hydrocarbons. The corrosion and abrasion issues related to handling brine, however, create integrity challenges that impact operational reliability and cost. A recent...

United Completes Longest Ever Tite Liner® Installation

Pipeline rehabilitation specialists, United Special Technical Services (USTS), a joint venture between United Pipeline Systems and STS, recently completed the longest-ever continuous compression fit Liner insertion project in its history. The project, undertaken using...

Underground Mine Selects United Pipeline Systems’ PreFit™ Solution for Production Line in Tunnel

Some pipeline applications require a small installation footprint. Instead of the typical field liner installation where a crew installs Tite Liner® on-site, PreFit™ pipe is lined offsite. The lined pipe is delivered by truck, ready for installation with...

Rotolined Fittings Solve Produced Water Challenges in the Permian Basin

Background A multinational energy company was facing a significant issue with its produced water pipelines in the Permian Basin. Epoxy-lined fittings, which were expected to provide long-term protection, had worn out in just five years, leading to corrosion of the...

Internal Corrosion Control of Steel Pipelines Addressed at Underground Hydrocarbon Storage Facility in Mexico

November 2017 Underground salt dome storage facilities provide a safe and efficient means of storing hydrocarbons. The corrosion and abrasion issues related to handling brine, however, create integrity challenges that impact operational reliability and cost. A recent...