Produced water has always been a part of oil and gas production, but in the Permian Basin and particularly in its Delaware Basin sub-basin, it has become one of the region’s most urgent infrastructure challenges. As output grows, so do the massive volumes of highly saline, highly corrosive water that operators must transport, treat, or dispose of safely. What was once a manageable byproduct is now a driving force behind large-scale pipeline buildouts, seismicity concerns, regulatory scrutiny, and escalating corrosion risks.

This overview explains what produced water is, why West Texas and southeastern New Mexico are seeing the most acute impacts, and how engineered internal lining solutions help operators protect their gathering and long‑haul water pipelines.

What Produced Water Is and Why It’s Hard to Manage

Produced water is the fluid that comes up with oil and gas during production. While its composition varies by formation, it often contains:

- Extremely high total dissolved solids (TDS) and chlorides that aggressively corrode steel

- CO₂, H₂S, and other gases that accelerate corrosion reactions

- Hydrocarbons, treatment chemicals, and organic compounds

- Suspended solids that contribute to erosion and abrasion

In the Permian Basin, water cuts are especially high—several barrels of water for every barrel of oil in many wells. This creates not only a disposal challenge but a significant infrastructure burden, as operators must continuously move massive volumes across long distances.

Why Produced Water Has Become a Growing Problem in the Delaware Basin

The challenge is not just chemistry; it’s a convergence of operational, geological, and regulatory pressures that are intensifying year over year.

Corrosion Is One of the Biggest Risks

Produced water is one of the most corrosive fluids encountered in oilfield operations. High chlorides, acid gases, and bacteria drive internal corrosion that can quickly degrade steel pipelines. For integrity engineers, this creates an ongoing risk of leaks, unplanned outages, and costly repairs.

Disposal Zones Are Reaching Capacity

The Delaware Basin is described by operators as “full.” Injection wells can no longer accept water at the same rates, forcing midstream water companies to transport water to new disposal areas—sometimes many miles away.

Beneficial Reuse Isn’t Ready Yet

There is strong industry interest in “beneficial reuse” (treating produced water for surface discharge or agricultural use). But today, the technology cannot reliably treat the volumes or chemistry at scale, and regulatory hurdles remain significant.

Seismicity Is Changing Water Logistics

Increased earthquake activity in West Texas has led regulators to restrict injection in certain areas. Operators must now reroute produced water to zones with fewer seismic constraints, often over long distances.

Where the Pressure Is Greatest: West Texas & Southeastern New Mexico

The Delaware Basin, stretching across far West Texas and into New Mexico, is one of the most productive regions in the country, and also one of the highest-volume produced water regions.

- West Texas: Midstream water operators manage extensive pipeline networks moving enormous volumes every day. Trucking remains part of the logistics mix, but at this scale, it is costly, slow, and creates safety risks.

- Southeastern New Mexico: Additional regulatory oversight and injection constraints push more water toward Texas and other regions.

As a result, operators are building longer, higher‑pressure pipelines to move water safely out of constrained areas.

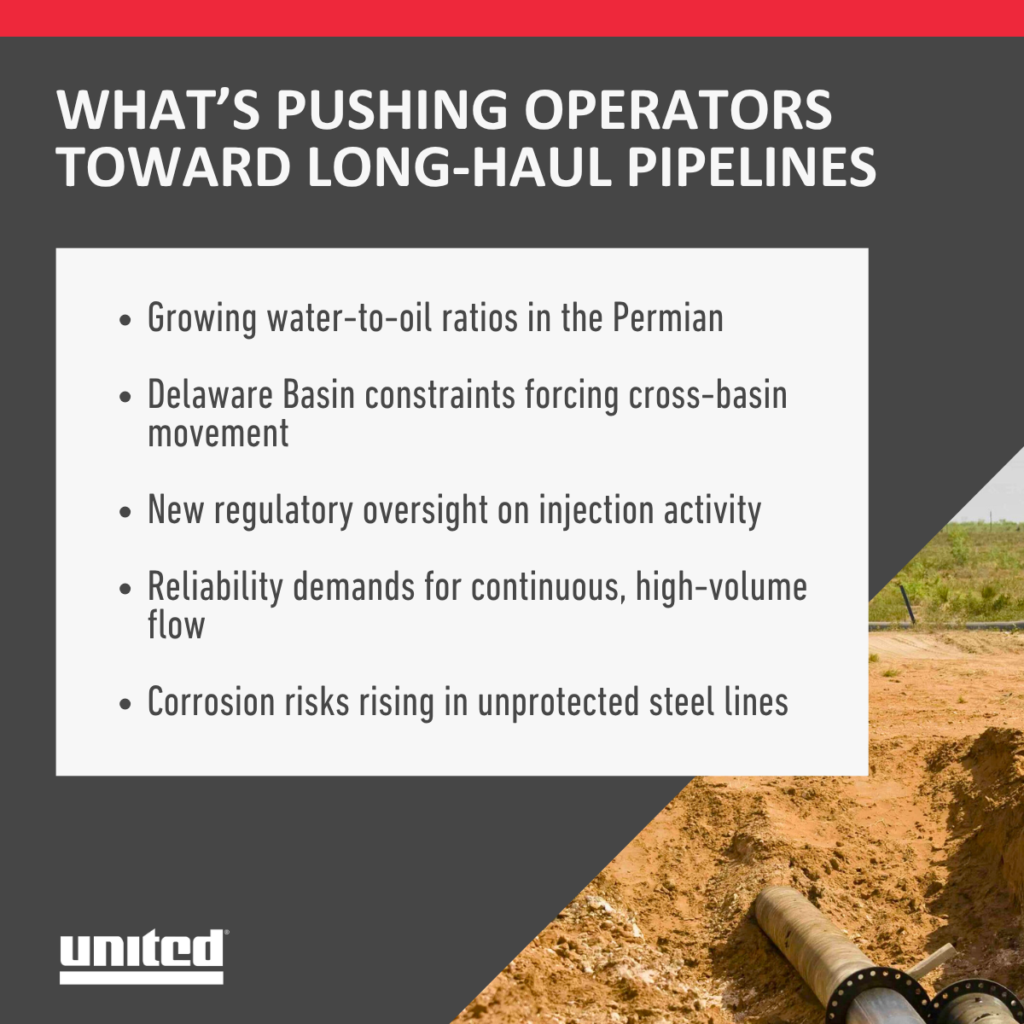

Why Long-Haul Produced Water Pipelines Are Becoming Standard

Pipeline operators are shifting to permanent, high‑capacity systems for several reasons:

- Efficiency: Pipelines move more water at lower long-term cost than trucking.

- Safety: Pipelines eliminate road traffic, reduce accidents, and minimize community disruption.

- Environmental performance: Fewer emissions and reduced surface impact.

- Operational reliability: Continuous, controlled flow—especially important when injection zones are far from producing fields.

But these longer systems also require higher pressures, faster velocities, and more robust corrosion control, heightening the need for engineered protection inside the pipe.

How United Pipeline Supports Reliable Produced Water Transport

Produced water lines face some of the harshest internal environments in the oilfield. United Pipeline provides engineered internal lining systems that allow operators to maintain the structural strength of steel pipelines while isolating the pipe wall from corrosive fluids.

Tite Liner®: A Proven Internal Lining System for Produced Water Pipelines

United Pipeline’s flagship solution, Tite Liner®, is a high‑density polyethylene (HDPE) lining system pulled into pipelines under compression. Once released, the liner expands tightly against the pipe wall, creating a durable corrosion barrier. Tite Liner®:

- Shields steel from corrosive chlorides, CO₂, H₂S, and bacteria

- Resists abrasion from sand and solids

- Supports both new construction and pipeline rehabilitation

- Withstands pressures tested up to 7,500 psi

- Is installed in long, fused segments that reduce field joints and potential leak points

These attributes make Tite Liner® well‑suited for the long-haul, high‑pressure produced water systems now common in the Delaware Basin.

PreFIT™ Lined Spools for Facilities and Complex Areas

For sections where field installation is challenging—facilities, tie‑ins, tight corridors—United offers PreFIT™ prefabricated lined steel spools. These provide:

- Consistent factory-applied lining quality

- Easy integration with field‑installed Tite Liner® systems

- Protection in high‑risk or complex segments of produced water infrastructure

Additional Capabilities for Produced Water Systems

United Pipeline also supports operators with:

- Specialized liner variants for high-temperature or harsh chemical conditions

- Advanced joining systems engineered for high‑pressure service

- Engineering support for surge analysis, material selection, and installation planning

The Bottom Line

Produced water management in the Delaware Basin is only becoming more complex. Rising volumes, disposal constraints, seismicity, and increasing transport distances demand reliable, corrosion‑resistant pipeline systems.

Long-haul pipelines are now the backbone of produced water logistics—but their success depends on protecting steel from the harsh chemistry inside.

Engineered internal lining systems like United Pipeline’s Tite Liner® help operators extend pipeline life, reduce failures, and maintain continuous, safe operations in one of the most demanding environments in the U.S.If your team is evaluating new produced water infrastructure or rehabilitating existing lines, United Pipeline’s engineering group can help assess lining options tailored to your operating conditions. Get in touch with our team today to learn more.